KABUL (Pajhwok): The Chamber of Industries and Mines (CIM) says Afghanistan has gained full self-sufficiency in 48 sectors and semi self-sufficiency in 19 other sectors.

However, CIM warns that all these sectors could collapse if their problems are not resolved.

Afghanistan relies on foreign aid and is an importing country as the Ministry of Industry and Commerce says Afghanistan had 86 percent of imports and 14 percent of exports last solar year.

However, officials at CIM say Afghanistan has become self-sufficient in 48 sectors and the country has more production capacity than its own needs.

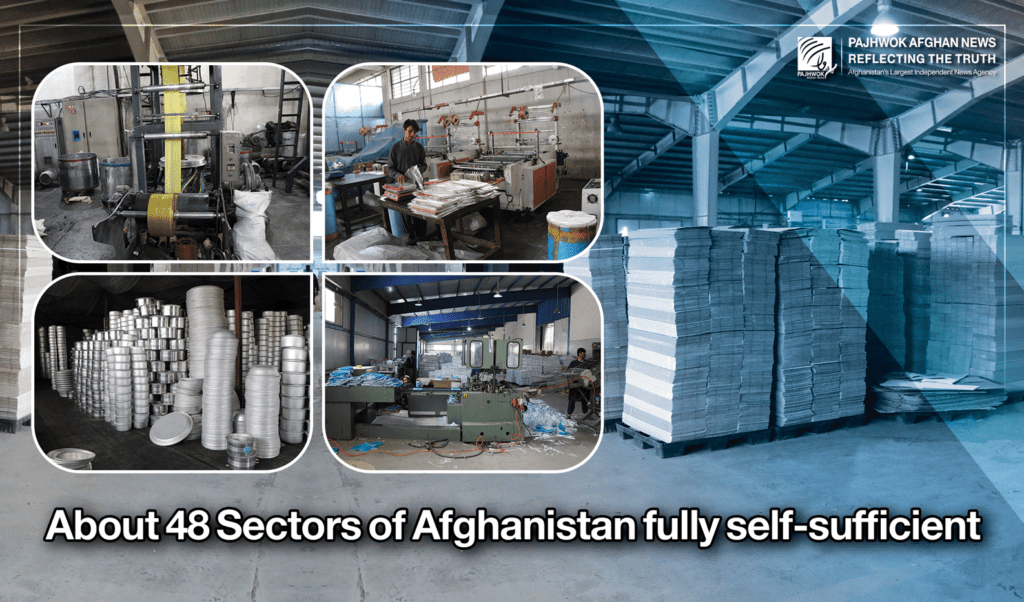

Among the 48 sectors are the printing sector, beverage production, pipe production, PVC, coal and gate production, packaging, saffron, aluminum, dried fruit, fuel and water tanks, detergents and others.

Among these sectors, Pajhwok News Agency randomly visited a number of factories in these sectors and asked questions about their business, production level and quality of their products.

Baheer Group of Factories has been active in the industrial sector in Afghanistan for the last 32 years and packaging, cardboard and paper production are some of its products in which Afghanistan has reached self-sufficiency.

NavedHakimi, the group chief executive, says that in the printing area, they have the ability to produce and package 250,000 to 300,000 volumes of books a day.

He said that Afghanistan has become self-sufficient in the printing sector and has even more production capacity than its own needs.

Hakimi added that their cardboard factory can produce 300,000 to 350,000 cardboard boxes a day while he said Afghanistan’s consumption capacity per day may not exceed 200,000 of these boxes.

“Afghanistan has also become self-sufficient in (A4) and (A3) paper production and can produce even more of its needs or over 17,000 tons a year,” he said.

Hakimi said that his factory alone could produce up to 55,000 tons of paper in a year, more than double the amount of domestic need.

He considered the export of Afghan paper to Kazakhstan for the first time a big step and said that the export was an example of Afghanistan’s self-sufficiency in the paper production sector.

He said that the quality of their products matched international standards and could compete with international products.

However, Hakimi considered lack of sustainable electricity and limitations on transfer of money to buy raw materials as serious problems for Afghan industrialists and called on the officials of the caretaker government to pay attention to solving these issues.

Raw materials cannot be fully obtained from domestic sources and need to be imported from foreign countries, he said.

Another sector that has reached self-sufficiency is iron melting and aluminum products.

Abdul Raziq, in charge of one of the factories of iron smelting and producing aluminum equipment, says that their factory has the ability to make any type of products from aluminum by order from their customers.

He said that their production has decreased following political changes in the country on August 15 last year.

He cited shortage of electricity and raw materials as challenges to their business and called on the government to address these issues.

Plastic bags is another sector that has become self-sufficient in the country.

One of the factories that produces different types of plastics, has created jobs for 300 people and can produce 20 to 25 tons of plastic every day.

BawarManali, in charge of the production section of this factory, says that they are able to produce up to about 50 tons per day.

He said that regime change in the country affected their business, but their business bounced back since the last one month.

However, he said there were some problems related to banks as they faced issues in transfer of money while importing raw materials in addition to electricity shortage that he added the government should resolve.

He asked the government to curb smuggling of goods from Iran, Pakistan and China into Afghanistan so it would help boost domestic products.

Manalai said that they also can recycle plastics.

RahimullahSamandar, chief executive of Chamber of Industries and Mines, referring to self-sufficient sectors, said, “These sectors have gained self-sufficiency in terms of quantity, quality and market demand.”

However, he said that shortage of electricity and raw materials, the problems in money transfer and telegraphic transfer, are among the major problems that the industrialists face and despite several meetings with officials, these issues are yet to be fully resolved.

He said that self-sufficient sectors will collapse if mentioned problems were not resolved.

“Industrialists were able to make these sectors self-sufficient, and now a strong government support is needed to maintain them,” he added.

On the other hand, Abdul Rahman Rahmani, commercial in charge in Da Afghanistan BreshnaSherkat (DABS), says that the company is always trying to create more facilities for the industrial sector of Afghanistan.

However, he said that Afghanistan’s electricity is mostly imported and DABS could not do more on the regard.

Pajhwok repeatedly tried to contact the Da Afghanistan Bank on the challenges faced by industrialists in the banking area, but failed.

mds/ma

GET IN TOUCH

NEWSLETTER

SUGGEST A STORY

PAJHWOK MOBILE APP